SHEET METAL

WORKSHOP 4.0

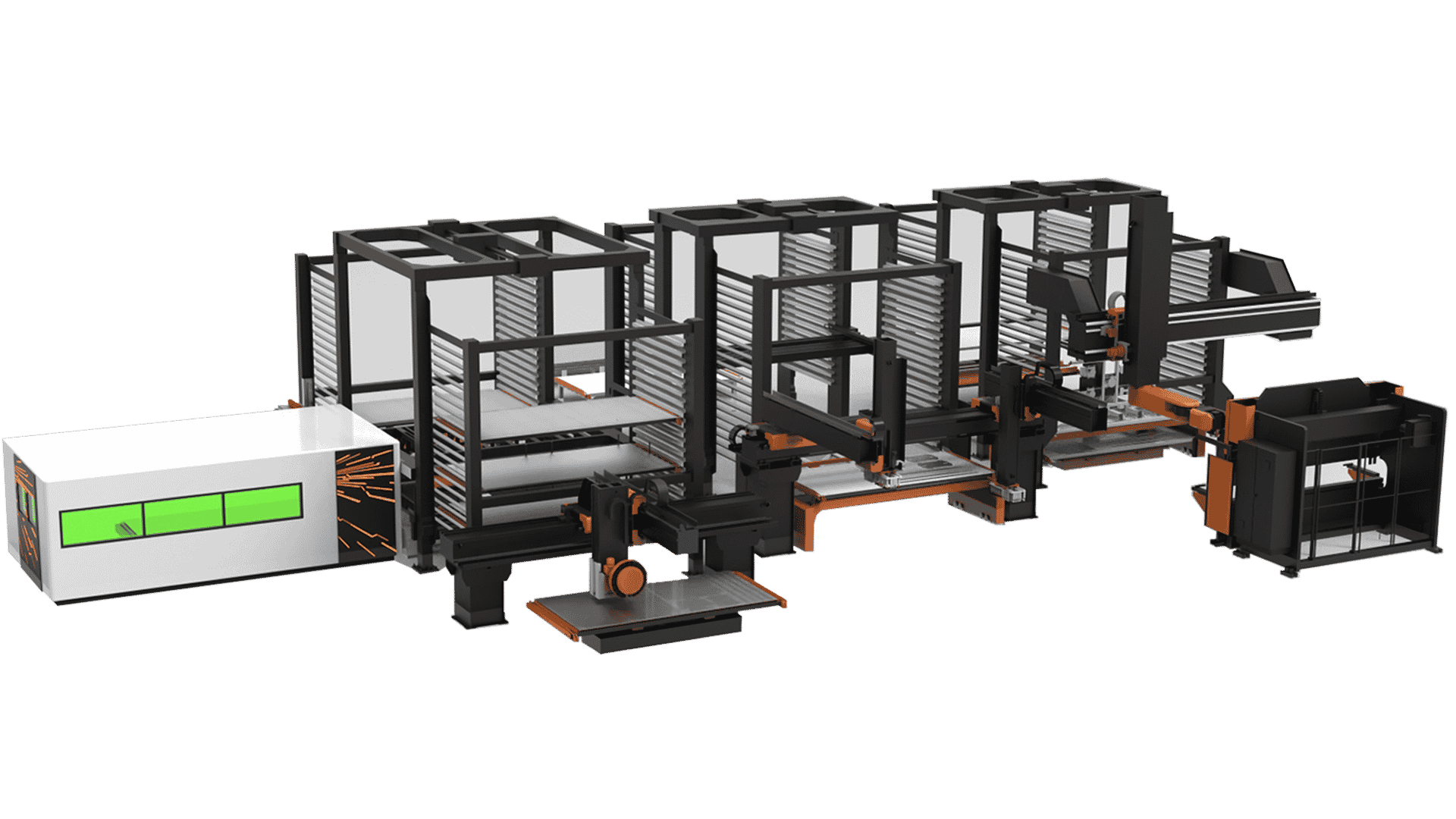

From cutting to storage, stripping, drilling, bending and many other applications, the Sheet Metal Workshops 4.0 was designed to manufacture sheet metal parts by the unit or in small quantities in order to increase productivity.

From this vision, a series of modular industrialised machines were developed that combine a storage system, a business system and an operational analysis tool for automated, quality production in an optimised timeframe.

These robotic peripheral automation systems have been designed to keep pace with the laser, thus allowing a rapid return on investment for our customers.

Whatever the configuration chosen, it will be possible to upgrade the system by adding additional robotic peripherals as our customers’ activities evolve.

Features

The Smart Tower System demonstrates its reliability and precision in the boiler making sector to automate an existing or new factory.

To guarantee maximum modularity, each Smart Tower has been designed independently to allow:

- Change pallets and controls quickly without stopping production.

- To be installed in different ways (staggered or aligned) with the linkage tables between them. These devices can be adapted to the different workstations and above all to the structure of the building.

- Manual or semi-automatic rework thanks to an ergonomic designed for the operators, leaving them enough space to go around the pallets and access every strategic point of the machines and robots.

Safety

Ergonomic workstation for manual or semi-automatic operations.

Accessibility

The man-machine interface has been simplified to the maximum on each screen and standardised on all workstations.

Preventive maintenance

Remote control of the machine’s status.

Customer service

A dedicated hotline is available to our customers to answer all their needs.

Logiciel

Easy to use, modular, remotely monitorable compatible with the cloud to big data etc. that tracks mechanical elements.

USE CASES

TRAC-C INSTALLS A MACHINING CENTER

As part of TRA-C industrie’s investment strategy and in order to optimise production times, services and costs, Tra-C has integrated a new OPTIPLEX 3015 Fibre III fibre laser cutting machine equipped with an Eazy Compact automatic storage system.“The factory of the future will be more agile and flexible, less costly and more respectful of its […]

THE NOEL GROUP INTEGRATES A NEW LASER

The Noel Group can be proud to have a unique laser with innovative technologies and being one of the few in France to be able to work on sheets up to 4 000 mm * 2 000 mm